|

詳細情報 |

|||

| 最小注文Quanlity: | 1pc | 価格: | negotiable |

|---|---|---|---|

| パックガーイングの詳細: | 合板パッケージ | 受渡し時間: | 45days |

| 支払条件: | T/T | 印刷速度: | 800-1100pcs/hour |

| パッケージの詳細: | 合板パッケージ | 証明: | CE |

| ハイライト: | 全自動スクリーン印刷機,プラスチック製の丸いバケツ型スクリーンプリンター,高速スクリーン印刷機 18pcs/min |

||

製品の説明

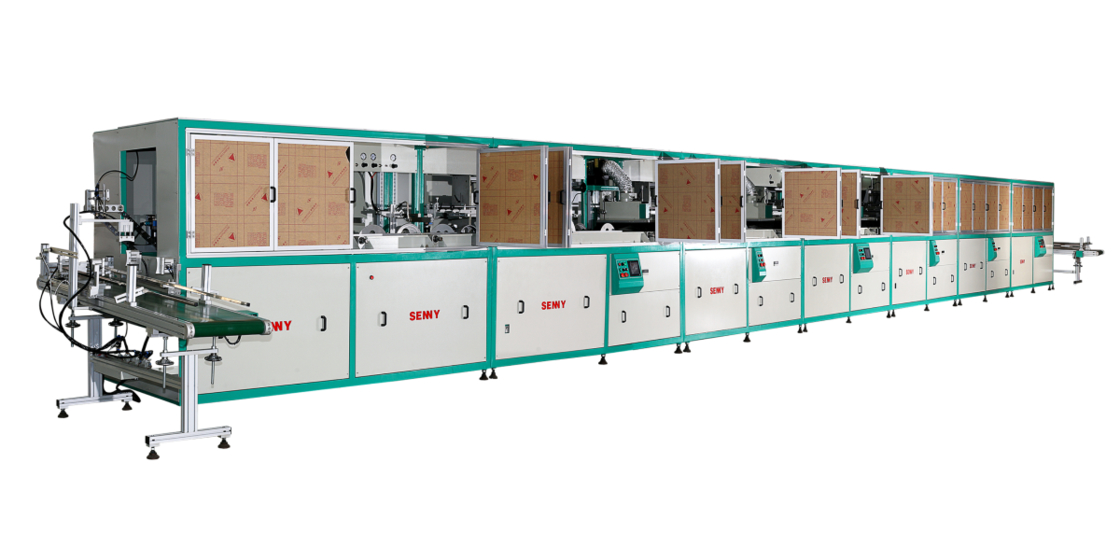

プラズマ表面処理 プラスチック丸いバケツ 完全自動スクリーン印刷機 18pcs/Min

製品

特徴

特殊用途:

精度目標: 標準の7Lから25Lのプラスチック丸いバケツに曲げられた表面を印刷するために特別に設計され,正確なパターン登録と強い粘着を保証します.

高度なプロセス:UV (紫外線硬化) インク技術を使用し,即時乾燥,生産効率の向上,高光輝度,強い磨損耐性のあるプリントを可能にします.優れた耐候性環境に与える利点です

優れた性能と信頼性

プレミアムコンポーネント保証:主要な電気コンポーネント (PLC,サーボシステム,インバーター,センサーなど) は,国際的に国内的に有名なブランド (例えばシメンス,三??,オムロン,シュナイダー)長期にわたって安定した動作と低故障率を保証します.

インテリジェント制御システム: ユーザーにやさしい大型産業用タッチスクリーンと高性能PLC制御システムで装備されています.直感的なインターフェースにより,パラメータの設定が簡単です.精密なプロセス制御生産管理を簡素化するデータ保存/リコールをサポートします.

多様 な モデル の 選択

色容量,生産速度,バケツ直径の互換性,自動化レベル (例えば,オプションの自動ロード/卸載) をカバーする複数のモデルと仕様が利用可能である.中小企業から大手製造業者までの様々なニーズと予算を正確に満たす.

高効率,安定性,使いやすさ

安定した動作: 精密な機械+高度な制御システムにより,高速/長連続走行において高い安定性,高印刷記録精度が保証される.

迅速な切り替え:最適化された機械とインテリジェント制御により,切り替え時間が大幅に短縮され (スクリーンプレート,インク色,バケツサイズ),機器の利用と生産の柔軟性が向上します.

操作は使いやすい:エルゴノミックなHMI,明確な表示,シンプルな設定,オプションの補助登録装置により操作は直感的で学習が簡単です.保守も便利です.操作者の技能要求を減らす.

|

マシンモードわかった

|

SL700

|

|

印刷速度

|

最大18個/分

|

|

丸いバケットの直径

|

150~350mm

|

|

丸いバケツの高さ

|

200×400mm

|

|

最大印刷長さ

|

900mm

|

|

最大印刷高さ

|

250mm

|

構成

貯蔵コンバーシーベルト

量検査機

プラズマ表面処理 (標準構成は炎表面処理)

![]()

給餌システム

![]()

固定装置と印がないバケツ

![]()

紫外線固化システム

![]()

印刷システム

![]()

申請

SL700自動プラスチックシリンダーUVスクリーン印刷機は,完全に自動的なシリンダ式スクリーン印刷ソリューションです.特にシリンダ式容器のために設計されています.プラスチック樽に耐久性のあるUVスクリーン印刷コスメティック,化学薬品,食品包装,および産業用用途で使用される丸い容器.

![]()

連絡先:

|

SENNY印刷設備株式会社

|

|

|

連絡先:

|

シエナ・シェン |

|

携帯電話/Whatsapp:

|

+86 13650136019 |

|

メール:

|

シエナ.シェン@センニー.コン.cn |