|

詳細情報 |

|||

| 自動グレード: | 完全に自動 | ブランド名: | SENNY |

|---|---|---|---|

| 受渡し時間: | 45days | 供給の能力: | 5pcs/月 |

| 支払条件: | T/T | アフターセールスサービス: | 合板パッケージ |

| 証明: | CE | 印刷期間: | 高い期間 |

| 保証: | 1年 | 色の印刷: | 2色 |

| ハイライト: | 2-color plasma bottle caps printer,high-speed caps printing machine 1600pcs/min,plasma surface treatment printing machine |

||

製品の説明

2-Color Plasma Surface Treatment Bottle Caps Printing Machine 1600pcs/Min

PRODUCT

Features

Exceptional Printing Speed & Production Capacity Matching:

Steplessly adjustable printing speed for precise alignment with customers' production cycles.

Easily meets diverse capacity requirements (from low-speed fine proofing to high-speed mass production) and enables seamless integration with cap injection molding machines or complete cap production lines.

Flexible Color Configuration & Precision Registration:

Modular design with multiple model options; standard configurations include 1-2 color or 1-4 color units.

Equipped with a high-precision electronic shaft registration system, achieving a multi-color registration accuracy of ±0.05mm, which ensures sharp and clear reproduction of complex patterns and fine text without ghosting.

Accurate and Controllable Ink Layer System:

Independently adjustable inking system: Each printing unit is equipped with a precision ink metering mechanism, ensuring ink supply of each color group is accurately matched to avoid color mixing or uneven inking.

Stepless ink film thickness control: Operators can precisely and easily adjust UV ink deposition (no need to replace parts) to meet varying process requirements – from ultra-thin base layers to heavy coverage – guaranteeing consistent color saturation across the entire print run.

Intelligent Operation & Convenient Maintenance:

Electronically controlled reverse operation: Simplifies setup, cleaning, and troubleshooting, reducing downtime for adjustments and significantly enhancing operational convenience and production continuity.

Removable console: Its ergonomic design allows flexible positioning (adapting to different workstation layouts) for optimal operator interaction, lowering fatigue during long shifts.

User-friendly Human-Machine Interface (HMI): Features a large color touchscreen with an intuitive graphical interface; parameter settings update in real time, status monitoring is clear, and fault diagnosis provides easy-to-understand prompts – even new operators can master it quickly.

Stable & Reliable Electrical & Control System:

Premium brand components: Critical electrical elements (e.g., PLCs, servo drives, inverters, sensors) utilize internationally renowned brands like Siemens, Omron, and Schneider, ensuring long-term stable operation.

Advanced control system: Based on a high-performance PLC (Programmable Logic Controller)core, integrated with HMI and servo drive technology for precise motion control, rapid response, and reliable logic.

High stability & low failure rate: Optimized system design and rigorous component selection guarantee exceptional reliability and extended service life in continuous production environments.

Technical parameters

| Machine Model | SOC2168 | SOC4328 |

| Cap Diameter | 28mm-38mm | 28mm-38mm |

| Max Speed | Up to 1600Pcs/Min | Up to 3200Pcs/Min |

| Printing Color | 2-4 color | 2-4 color |

| Printing Area | 24mm-34mm | 24mm-34mm |

| Air Consumption | 600L/Min | 600L/Min |

| Gas Consumption | 150L/Min | 150L/Min |

| Power | 3p 380v 50/60Hz | 3p 380v 50/60Hz |

| Air | 5-7 Bar | 5-7 Bar |

Configuration

- Plasma surface treatment(standrad condiguration is flame surface treatment)

- Bottle sorting machine

- Quanlity inspection machine

UV curing flame tratment device

![]()

![]()

Applications

SOC2168 Automatic Bottle Cap Dual-Color UV Offset Printing Machine is a fully automatic bottle cap dual-color UV offset printing machine. The application scope is very widely and it can be used for high-precision UV offset printing of various plastic bottle caps such as PCO1881, PCO1810, 28mm, 38mm caps; PP caps, PE caps, PET caps, cosmetic caps, pharmaceutical caps, beverage caps, etc.

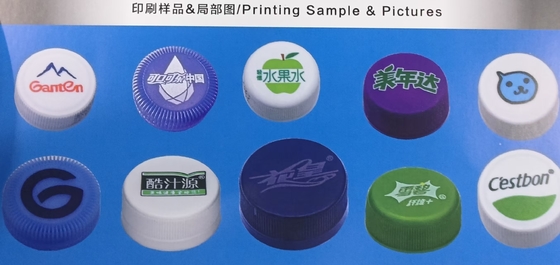

Printing sample

![]()

About us

SENNY PRINTING EQUIPMENT CO.,LTD was established in the year 2004, it is specialized in designing and manufacturing precise automatic screen printing machines, stick labler machines, hot stamping machines and auxiliary equipments. Meanwhile, they can design any kinds of automatic printing machines according to customers' requirements.

SENNY has very good designers. The founder of SENNY was engaged in designing and developing screen printing machines early from the year 1994, and he got many achievements: he designed the first automatic screen printing machine; automatic screen printing machine for big iron pails; four colors sereen printing machine for big oil kettles; automatic screen printing machines controlled by module independently for bottles; automatic screen printing machine for pails from 10L 1o 20L(3colors and 7colors) and so on so forth.

In order to improve our products, SENNY adopts the advantages of the similar products in or abroad, and we also take customers' comments and suggestions into consideration. With the innovation and improvement for many years, the products produced by SENNY now are in a leading position in the domestic markets. And it also sales well all around the world.

With the mission“Excellence,Creation,Sincerity,Quality!”,SENNY insists on providing high--quality products and services, dedicating to exploring the new markets and seeking for mutual benefit and win-win state with our customers.

![]()

![]()